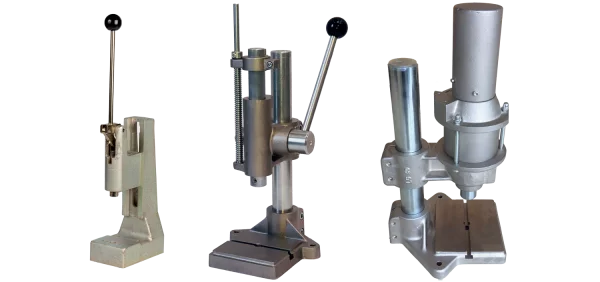

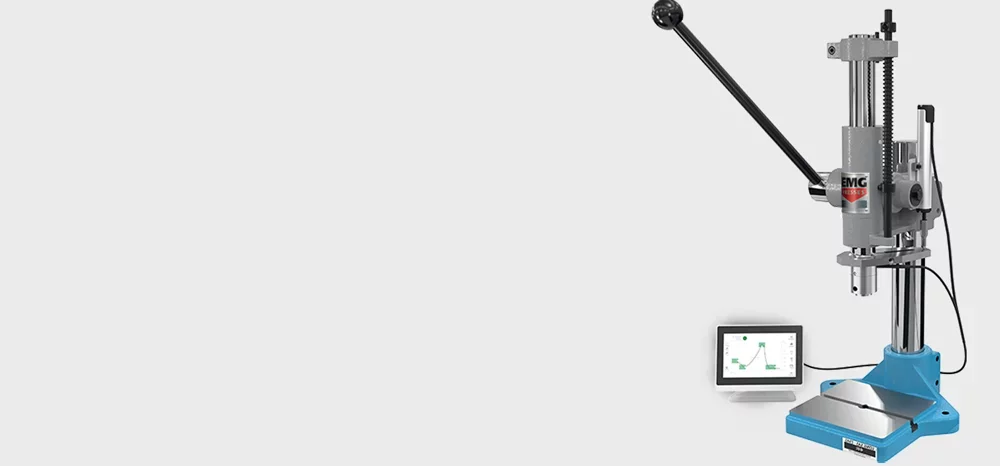

Manual rack presses

The EMG range of manual rack and pinion presses comprises two different types of press :

* Rack and pinion manual presses whose power, from 200 to 600 kg, is linear and constant over the entire stroke depending on the force exerted on the machine lever. They can be used in workshops for assembly operations, bearing and ring assembly, crimping, small bending operations, etc...

* High-capacity manual rack-and-pinion presses, which complete the range of rack-and-pinion presses. With capacities ranging from 1400 kg to 5000 kg, these models are perfectly suited to applications such as assembly, deep-drawing and all applications requiring significant travel and/or headroom.

Together with toggle manual presses and high-capacity toggle manual presses, they make up EMG's extensive range of manual presses.

| Power200 kg |

| Stroke0 » 50 mm |

| Swan-neck depth72 mm |

| Clear height54 » 200 mm |

| Weight8 kg |

| Power400 kg |

| Stroke0 » 80 mm |

| Swan-neck depth80 mm |

| Clear height35 » 270* mm |

| Weight17 kg |

| Power600 kg |

| Stroke0 » 100 mm |

| Swan-neck depth95 mm |

| Clear height46 » 280* mm |

| Weight25 kg |

| Power600 kg |

| Stroke0 » 100 mm |

| Swan-neck depth155 mm |

| Clear height30 » 400 mm |

| Weight38 kg |

| Power600 kg |

| Stroke0 » 100 mm |

| Swan-neck depth350 mm |

| Clear height95 » 305 |

| Weight95 kg |

| Power1 400 kg |

| Stroke0 » 420 mm |

| Swan-neck depth210 mm |

| Clear height420 mm |

| Weight45 kg |

| Power1 800 kg |

| Stroke0 » 420 mm |

| Swan-neck depth210 mm |

| Clear height420 mm |

| Weight50 kg |

| Power5 000 kg |

| Stroke0 » 530 mm |

| Swan-neck depth250 mm |

| Clear height530 mm |

| Weight145 kg |

| Power5 000 kg |

| Stroke270 » 800 mm |

| Swan-neck depth310 mm |

| Clear height800 mm |

| Weight145 kg |

| Power5 000 kg |

| Stroke530 mm |

| Swan-neck depth300 mm |

| Clear height415 » 1015 mm |

| Weight210 kg |

Applications

MAIN FEATURES

Force / stroke monitoring

MANUAL AND PNEUMATIC PRESSES

EMG offers all types of force and/or displacement management, with force and displacement transducer solutions to suit every need, for 100% part control.

Non return system

FOR MANUAL PRESSES

Anti-return system: prevents the lever from rising if the end of travel is not reached (guarantees complete and reproducible execution of the operation).

Features of manual bench presses:

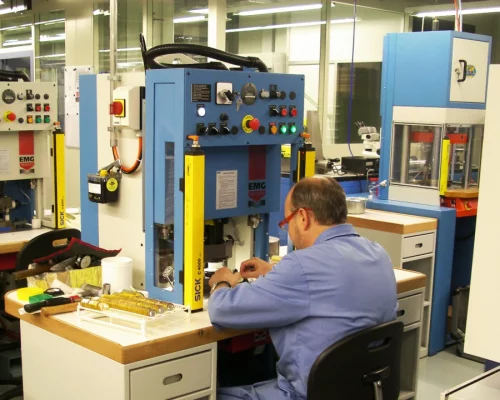

Manufactured in France and ISO-9001 certified since 2000, the EMG range of manual bench presses offers a wide choice of options and adaptations to meet the most diverse professional needs.

Multifunctional, they are ideal for a wide range of applications in both industry and construction. The weight of manual rack-and-pinion presses means they can be used free-standing on a workbench.

The base of some machines can be fixed to the workbench to ensure that the operator can work in complete safety. Our tools feature ergonomic handles and handwheels to facilitate cutting, riveting, assembly and other operations.

The most varied operations are carried out smoothly thanks to the power reserve of each model and the rigorous overall precision.

- Adjustable headroom and stroke

- Quick and easy to set up

- Low investment

LONG is also committed to designing and equipping the special machines required by the specific activities of each trade. To meet the needs of specific applications required by certain trades and fields of activity, EMG offers custom-made special equipment, perfectly adapted to specifications and production constraints.

Thanks to its design office and a fleet of more than 40 machining centres, EMG can design and manufacture any modification or special presses on request, as well as small press fittings and tooling, such as :

- Press with offset toggle to increase the depth of the gooseneck and the work table.

- Press with a tool for crimping 3 rivets to hold a steel part in a stainless steel support.

- Pneumatic press with 2-position cutting tool incorporating a top deflector for part ejection.

- Pneumatic press with electric control panel

APPLICATIONS

Bench-top manual presses can be used to assemble many different types of product. Multifunctional, they are suitable for small production runs of small to medium-sized parts, with professional results, even over long strokes of 500 mm.

Although they are less suited to bending than pneumatic or mechanical presses, manual presses can be very effective at bending different materials. It is important to check the characteristics of the manual press, including its permissible pressing force, to ensure that the desired result is achieved.

Whatever the intended operation, the operator manipulates the lever or handwheel to apply the necessary pressure throughout the stroke. The presses are easy to use, and the effort management system enables the quality of the various applications carried out with the press to be controlled quickly and accurately throughout the process.

An EMG manual press is delivered with a service manual, CE conformity certificate and drawings. It comes with a full one-year parts, labour and travel warranty.

An EMG manual press is delivered with a service manual, CE certificate of conformity and drawings. It comes with a full one-year parts, labour and travel warranty.