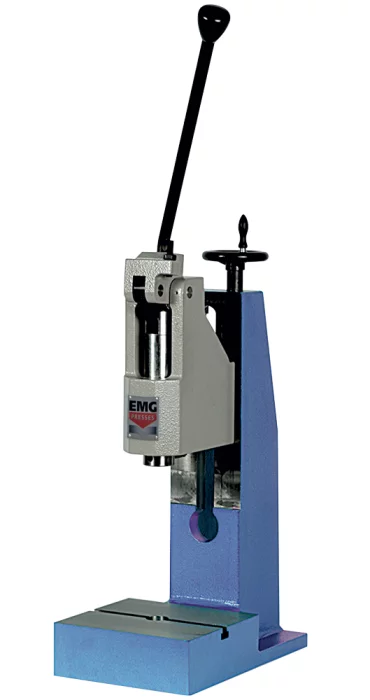

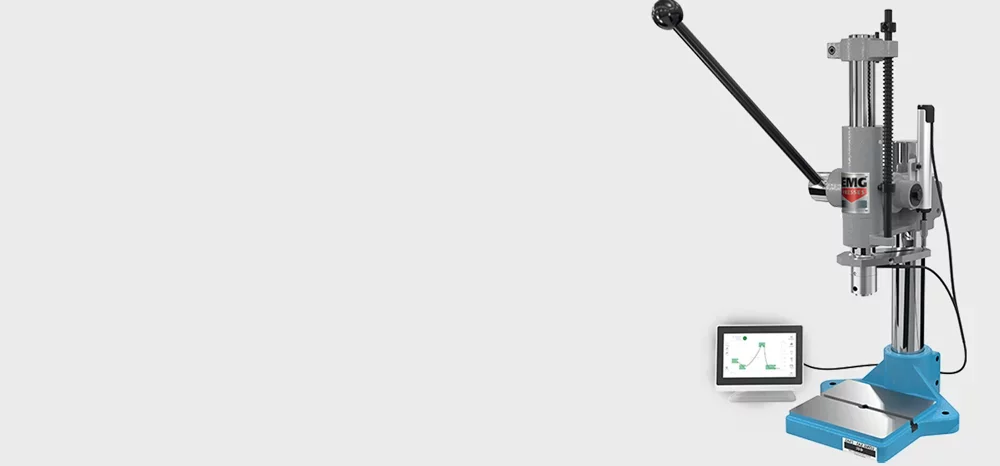

Manual toggle presses

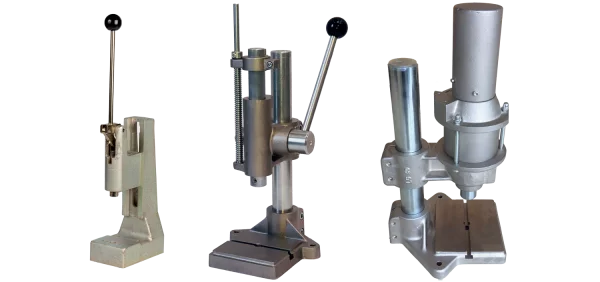

The EMG range of manual toggle presses comprises two different types of press :

- Manual toggle presses where the maximum power, from 500 to 2000 kg, is obtained only at the end of the stroke depending on the force exerted on the lever.

- High-capacity manual toggle presses, which have significantly higher capacities than their standard counterparts.

These presses are robust, precise, flexible and ergonomic.

They are frequently used for assembly operations, cutting thin products, small bends, various crimping operations and all applications requiring significant travel and/or headroom.

Quick and easy to use, they are also economical. They require very little investment.

Together with the 2 other types of manual press - rack and pinion manual presses and high-capacity rack and pinion manual presses - they make up the extensive range of EMG manual presses.

| Power1 500 kg |

| Stroke30 ou 60 mm |

| Swan-neck depth102 mm |

| Clear height60 » 250 mm |

| Weight32 kg |

| Power700 kg |

| Stroke40 mm |

| Swan-neck depth350 mm |

| Clear height80 » 270 mm |

| Weight95 kg |

| Power1 500 kg |

| Stroke30 ou 60 mm |

| Swan-neck depth220 mm |

| Clear height220 » 280 mm |

| Weight55 kg |

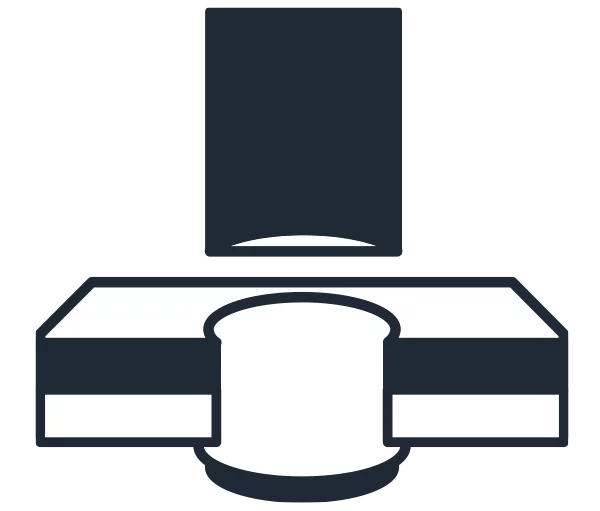

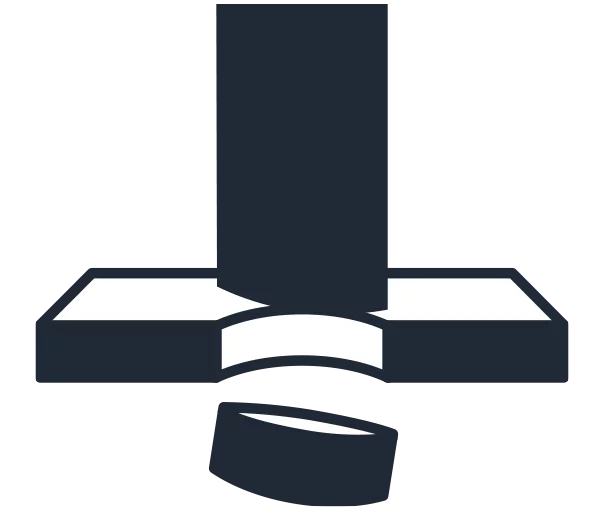

Applications

MAIN FEATURES

Force / stroke monitoring

MANUAL AND PNEUMATIC PRESSES

EMG offers all types of force and/or displacement management thanks to force and displacement sensor solutions adapted to each need, for 100% part control.

Non return system

FOR MANUAL PRESSES

Non return system: prevents the lever from rising if the end of travel is not reached.

This ensures that every operation is carried out completely and reproducibly.

Features :

- Ground and rotationally locked slide

- Automatic spring return of the slide

- Quick and reliable free height adjustment

- Precise adjustment of bottom dead centre by a mechanical stop to ensure cycle repeatability

- FGL 250 cast iron base and head for strength and rigidity

- Maintenance-free and grease-free

- Predisposed for mounting on a workbench

- Paint: 5015 Sky Blue base - RAL 7036 Platinum Grey head

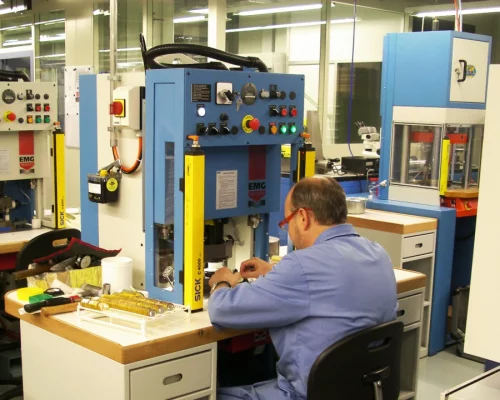

Manufactured in France and ISO-9001 certified since 2000, the EMG range of manual presses offers a wide choice of options and adaptations to meet the most diverse needs and requirements of each application, in industry as well as in the building trade.

The most varied operations are carried out smoothly thanks to the power reserve of each model and the rigorous overall precision.

- Adjustable headroom and stroke

- Quick and easy to set up

- Low investment

LONG is also committed to designing and equipping the special machines required by the specific activities of each trade. To meet the needs of specific applications required by certain trades and fields of activity, EMG offers custom-made special equipment, perfectly adapted to specifications and production constraints.

Thanks to its design office and a fleet of more than 40 machining centres, EMG can design and manufacture any modification or special presses on request, as well as small press fittings and tooling, such as :

- Press with offset toggle to increase the depth of the gooseneck and the work table.

- Press with a tool for crimping 3 rivets to hold a steel part in a stainless steel support.

- Pneumatic press with 2-position cutting tool incorporating a top deflector for part ejection.

- Pneumatic press with electric control panel

APPLICATIONS

Manual toggle presses are mainly used for applications requiring a high level of effort at a low height, such as cutting, crimping and marking. They are suitable for small production runs of small to medium-sized parts.

On manual presses with toggle levers, movement of the lever is very fast and ergonomic, as it is done through a maximum of 90° to cover the entire stroke of the press. The nominal pressure developed by this type of press is obtained at the end of the stroke.

The force management system enables the quality of the various applications carried out with the press to be controlled quickly and accurately.

An EMG manual press is delivered with a service manual, CE conformity certificate and drawings. It comes with a full one-year parts, labour and travel warranty.