Mechanical eccentric presses

The range of EMG mechanical presses consist of 5 models from 6 to 80 T.

Being performance-oriented, these execute the most demanding applications with precision and reliability: watchmaking, jewellery, mechanical optics, electrical and electronic machines, automotive industry, electrical goods, toys, locksmithing...

Being durable, these guarantee you optimum quality and unparalleled productivity for a very long time! The various operations are executed carefully thanks to the power reserve of each model and a very rigorous precision.

- Complies with CE standards (3 CE type approvals)

- Stroke change and adjustment of the quick release ball screw

- Robustness and reliability of the press and its components

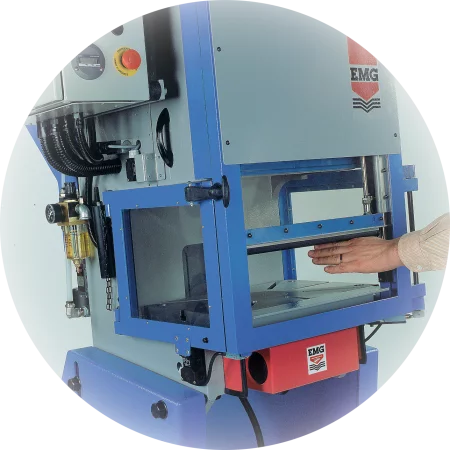

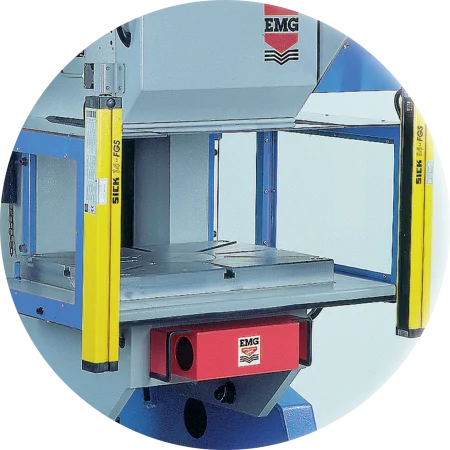

- More security to gain in productivity (screen - electronic guards)

| Variable stroke4 » 40 mm |

| Swan-neck depth120 mm |

| Table dimensioning450x220x30 mm |

| Number of cycle / min240 |

| Clear height200 mm |

| Swivel screw adjustment0 » 30 mm |

| Weight450 kg |

| Variable stroke5 » 75 mm |

| Swan-neck depth180 mm |

| Table dimensioning450x320x40 mm |

| Number of cycle / min140 |

| Clear height300 mm |

| Swivel screw adjustment0 » 50 mm |

| Weight900 kg |

| Variable stroke5 » 75 mm |

| Swan-neck depth210 mm |

| Table dimensioning550x400x48 mm |

| Number of cycle / min140 |

| Clear height300 mm |

| Swivel screw adjustment0 » 60 mm |

| Weight1 400 kg |

| Variable stroke6 » 100 mm |

| Swan-neck depth220 mm |

| Table dimensioning650x430x57 mm |

| Number of cycle / min130 |

| Clear height350 mm |

| Swivel screw adjustment0 » 70 mm |

| Weight3 100 kg |

Applications

MAIN FEATURES

Main caracteristics of an EMG mechanical press :

Frame :

The frame is made of high quality mechanized-welded steel with swan-neck structure. Regular weld seams and proper welding supports ensure an exceptional rigidity and a resistance against cutting impacts even during an intensive use.

The very thick sides of the frame reduce the swanneck opening.

Shaft :

The shaft is made of hardened forged steel. An over-sulfinization after machining reduces the wear and tear due to friction. It runs on lubricated rings.

Stroke change :

The stroke change is achieved very quickly by turning the disconnecting device a ¼” of a turn and then selecting the desired Stroke length.

Slider :

The slider is made of cast iron FGS 300 mounted on steel or bronze sliding rails, adjustable by screws. The assembly is completely adjusted and scraped manually.

The adjustment is carried out by stops mounted on the press frame.

The bedplate of the slider has holes and a central bore for fixing tools.

The sliding rails have machining in the form of "oil grooves" allowing an efficient lubrication.

A knock-out bar goes through the slider. The adjustment is carried out by a stop mounted on the frame.

Lubrification :

The lubrication is centralized and ensured by a manual pump. The frequencies are to be adapted as per the cycles used (single or continuous stroke working).

Automatic pump (optional).

Twin-body solenoid valve :

It is self-controlled and assembled with heavy duty silencers.

Connecting rod/Swivel screw :

The connecting rod is made of FGS 300 cast iron (steel on 80T) with bronze line completely scraped ensuring a perfect lubrication. It is lubricated by oil.

The swivel screw is made of pre-treated steel, completed by a surface treatment.

Clutch/Brake :

The movements of the press are obtained by a monodisc air clutch and managed by a brake. An air reservoir compensates for the possible failures of the network starting from the 25t model.

Standard Equipment

-

Two hand controls with push buttons.

-

Central greasing by manual pump

-

6 digit counter with reset function, 8 digit counter without reset function

-

Single or continuous stroke

-

20° inclinable frame (option 45t and 80t)

-

Regulation with or without motor

-

Positive ejector in the slider

-

Balancing cylinders (45t and 80t)

-

Slider hydraulic unblocking (45t and 80t)

-

Automatic unblocking for the stroke adjustment (80t)

-

EC compliance certificate

-

User manual and electrical, pneumatic and hydraulic diagrams

-

Periodical verification guide (regulatory follow-up, verification procedures, preventive maintenance, faults and remedies)

APPLICATIONS

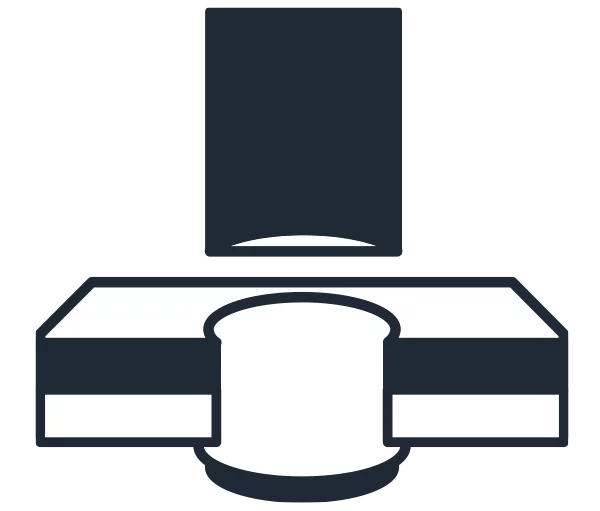

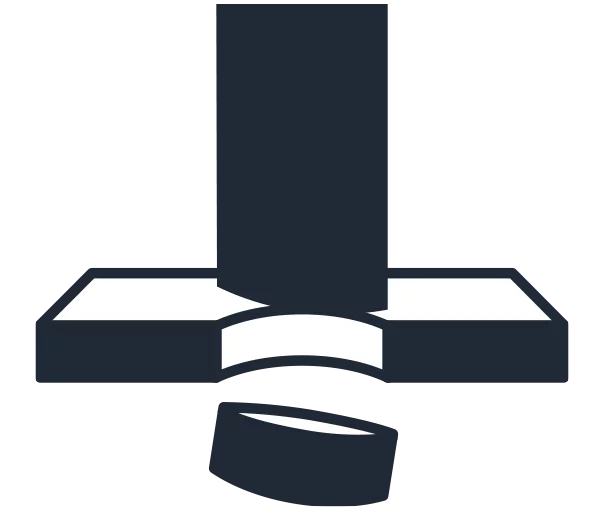

EMG has developed a range of mechanical presses from 6 tons to large tonnages (80 tons) particularly adapted to the stamping of all types of sheets. They are also adapted to the cutting/forming of complex parts thanks to the easy management of the force and the control of the pressure exerted throughout the operation.

How does a mechanical press work?

All the mechanical adjustments on board the press make it easy to adjust the speed, headroom and ram travel required for the application.

Bronze guides guide the ram as it descends from top to bottom, to ensure perfect alignment between the lower part of the tool fixed to the table and the upper part of the tool fixed to the ram. The strength of the frame's gooseneck counterbalances the considerable force applied (up to 80 tonnes) by the ram.

Faster than hydraulic presses, they offer very high repeatability with a low risk of breakdown.