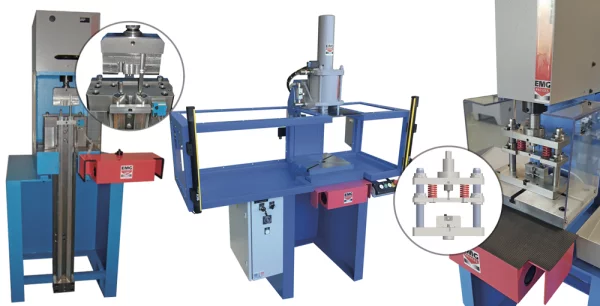

Hydropneumatic presses

EMG hydropneumatic presses, otherwise known as oleopneumatic presses, are machine tools that deliver high levels of power and precision. A true technological tool, operating with compressed air only, they are powerful and economical. Particularly well-suited to riveting and bending metals, their power can reach 100 tonnes. Each frame is adapted to the power of the cylinder.

| Power*6 910 » 7 820 kg |

| Total stroke*50 » 400 mm |

| Power stroke*6 » 40 mm |

| Swan-neck depth185 mm |

| Clear height400 mm |

| Weight500 kg |

| Power*13 380 » 14 000 kg |

| Total stroke*50 » 300 mm |

| Power stroke*6 » 40 mm |

| Swan-neck depth220 mm |

| Clear height430 mm |

| Weight750 kg |

| Power*28 300 » 30 650 kg |

| Total stroke*50 » 400 mm |

| Power stroke*6 » 40 mm |

| Swan-neck depth250 mm |

| Clear height500 mm |

| Weight1 200 kg |

| Power*45 900 » 47 600 kg |

| Total stroke*70 » 400 mm |

| Power stroke*6 » 40 mm |

| Swan-neck depth270 mm |

| Clear height580 mm |

| Weight2 200 kg |

| Power*72 700 kg |

| Total stroke*100 » 300 mm |

| Power stroke*10 » 16 mm |

| Swan-neck depth270 mm |

| Clear height670 mm |

| Weight4 500 kg |

Applications

MAIN FEATURES

CHARACTERISTICS OF AN EMG HYDROPNEUMATIC PRESS:

Our cylinder is a compressed air cylinder with closed hydraulic circuits, which allows attaining the requested loads with a stroke which is triggered when the piston gets a resistance. The action is very simple and similar to pneumatic double effect cylinders. This technology thus combines the advantages of both pneumatic and hydraulic systems, without any adverse effects (these include for example, no noisy, dirty hydraulic motors, and low air consumption). The result is perfect workmanship on every part, whatever the application.

|

|

|

|

|

|

Economical and silent, our presses require little or no maintenance. Compared with manual presses, they offer greater power, stroke, speed and quality of execution, for perfect results on every operation or machined part.

Our range of presses has :

- 6 different standard frames and 60 cylinders allowing an unlimited number of combinations.

- a power from 7 to 100 tons.

- a total stroke from 50 to 300 mm.

- a working stroke from 6 to 60 mm.

- 4 feet for guaranteed stability.

Our commitment

EMG has been a French manufacturer of bench, workshop and industrial presses for over 50 years. Quality is our priority. For us, it's the result of a flawless process. Our aim is to design the perfect oleo-pneumatic press to meet your needs, while respecting 5 essential commitments:

- a work in the rules of the art

- guaranteed long-term strength

- fast delivery times

- a very good quality/price ratio

- a total listening and understanding of your expectations.

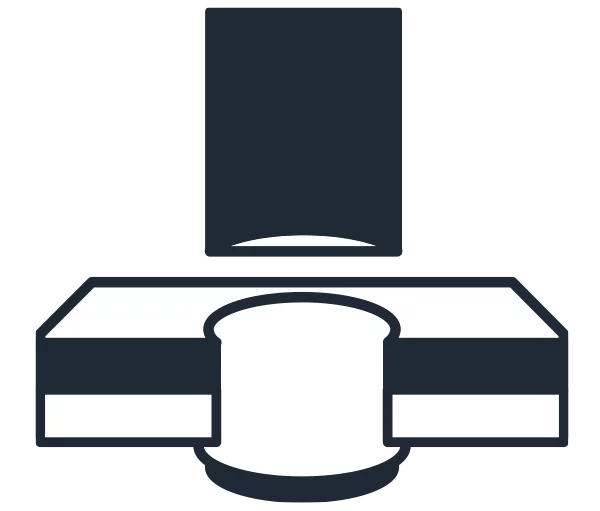

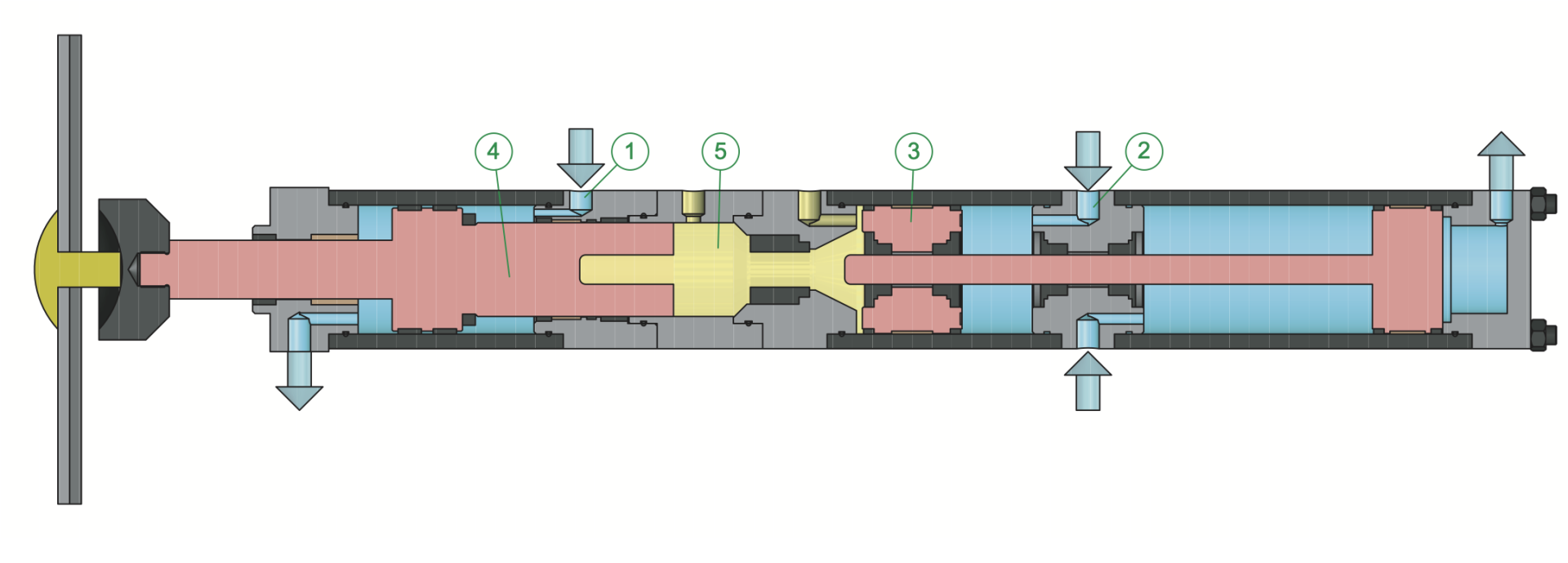

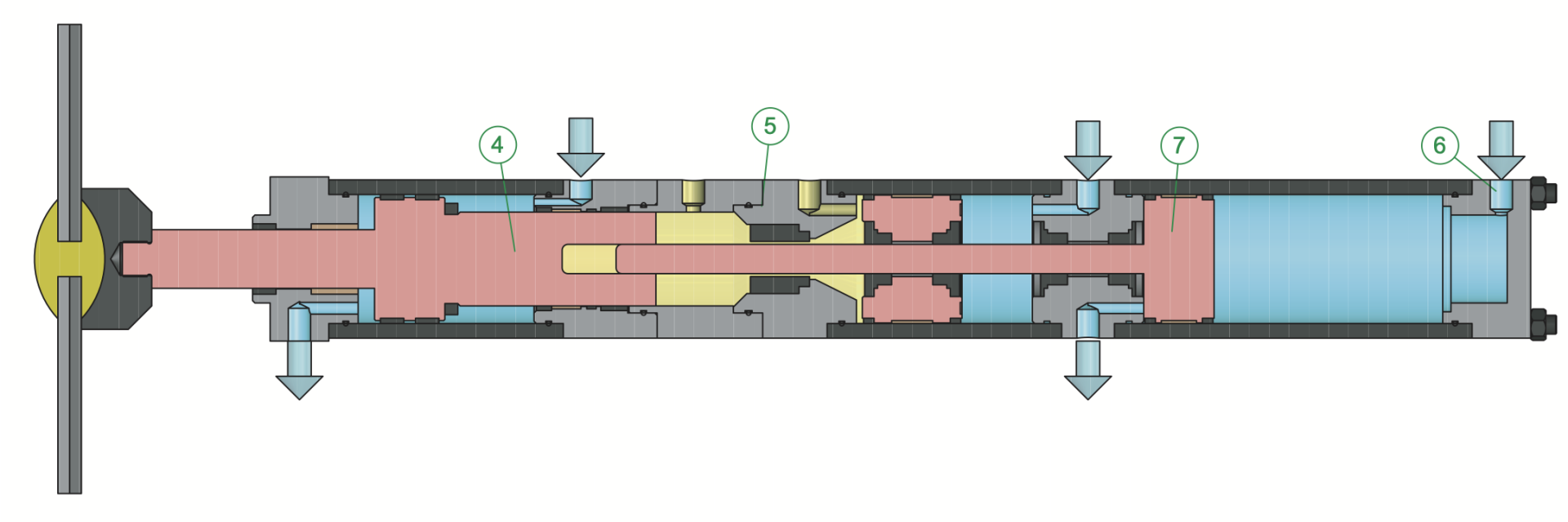

Explanatory Diagram of Operation

The fast approach run without power

The cylinder is supplied with compressed air at the marks (1) and (2). The rapid but rapid yet controlled descent of the feed piston (3) and the slider (4) takes place until resistance is reached. In this step, the oil fills the hydraulic chamber (5).

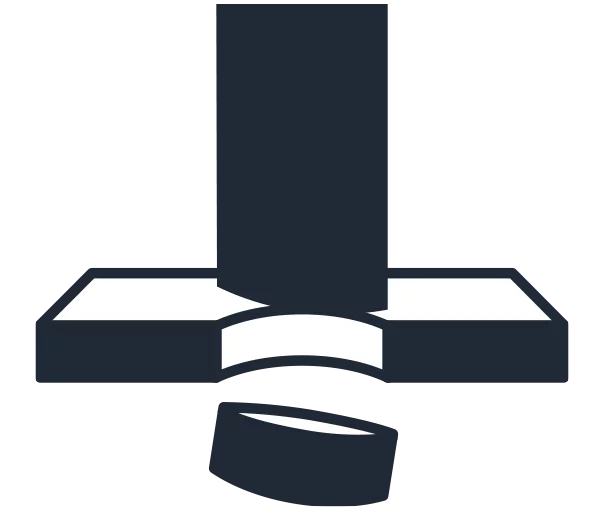

The slow working stroke with power

A control valve switches the pneumatic supply to the mark (6), the working piston (7) descends. During this phase, the plunger rod of the working piston (7) enters in the hydraulic chamber (5), compresses the oil, which greatly increases the power of the slider (4).

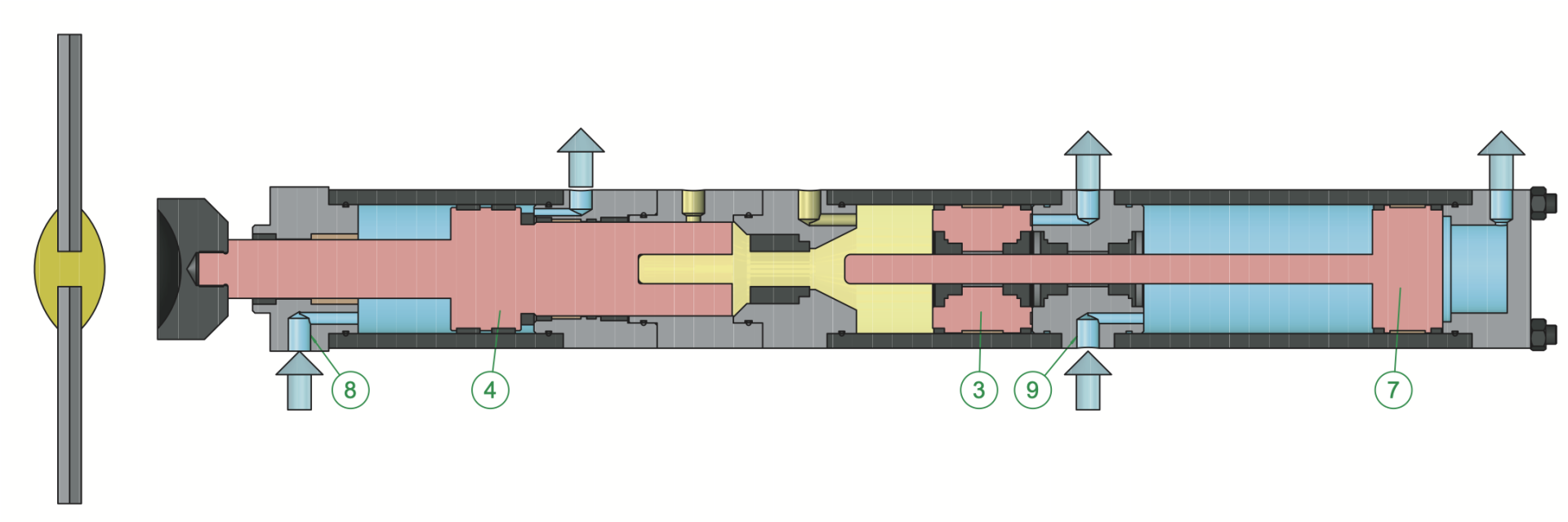

The return stroke and the stand-by position

The cylinder is supplied with compressed air on the marks (8) and (9). The slider (4), the feed piston (3) and the working piston (7) rise at high speed and remain held in the high position.

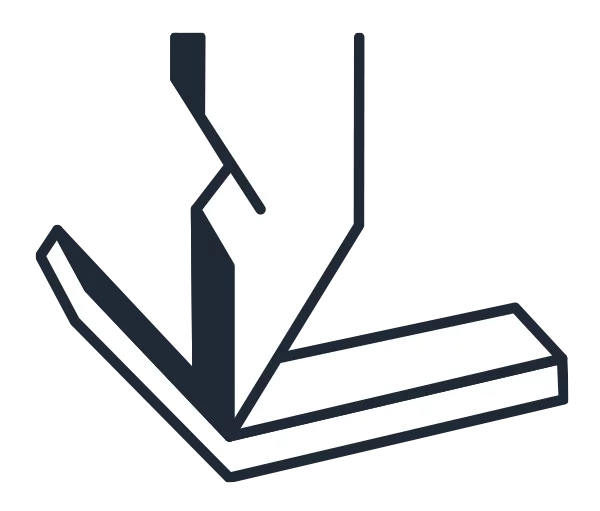

APPLICATIONS

Hydro-pneumatic presses deliver high power and precision, particularly at the end of the stroke. They are therefore ideally suited to riveting and bending all types of parts. Both of these applications require appropriate lowering speed management, with greater force at the end of the stroke, both for riveting and for bending sheet metal.