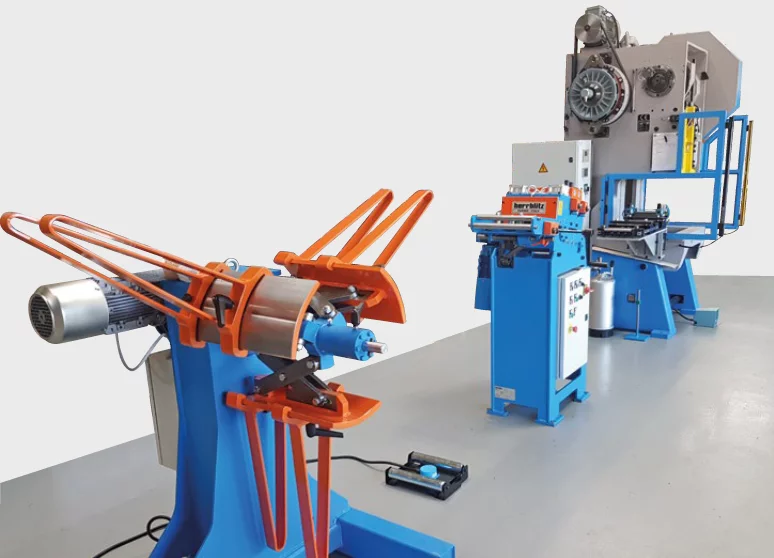

Production line

WITH UNWINDER, STRAIGHTENER, FEEDER

EMG designs a range of full production lines: strip feeder lines, wire feeder lines, length cutout lines including a wide product line of decoilers and straighteners and which can be adapted to any type of material or strip dimensions.

EMG PRESSE creates full and customized manufacturing lines

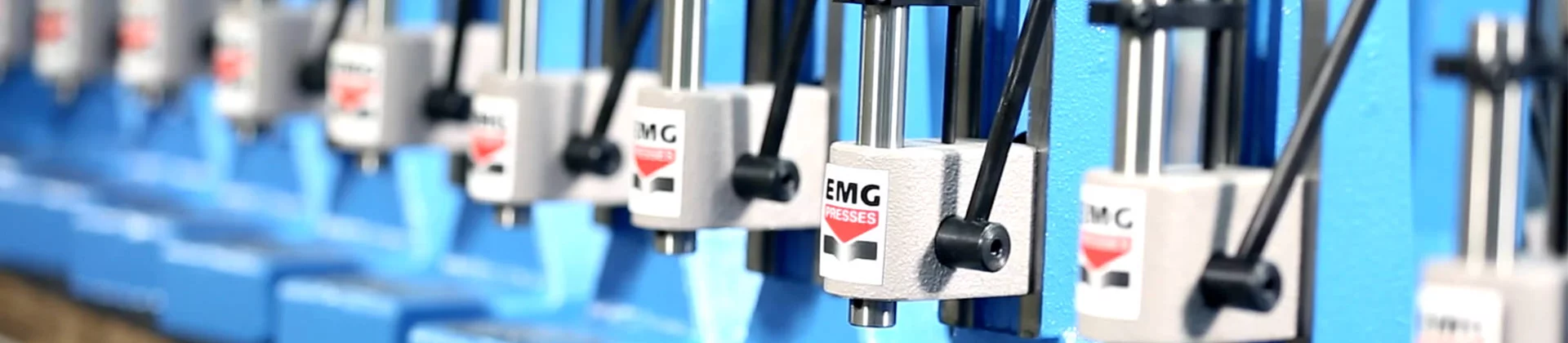

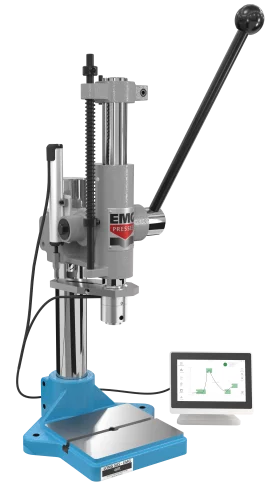

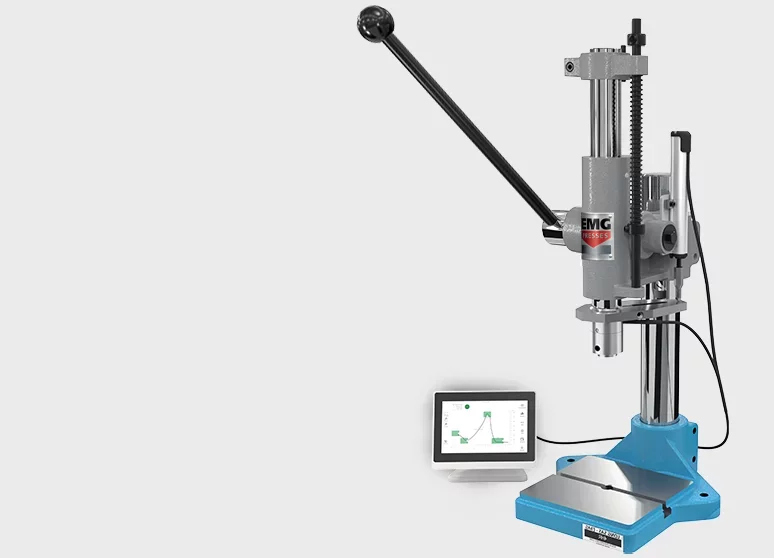

Force Monitoring

FOR MANUAL AND PNEUMATIC PRESSES

EMG offers all types of force and/or displacement management, with force and displacement transducer solutions to suit every need, for 100% part control.

Permanent quality control, Product process control, Total traceability and Monitoring the production.

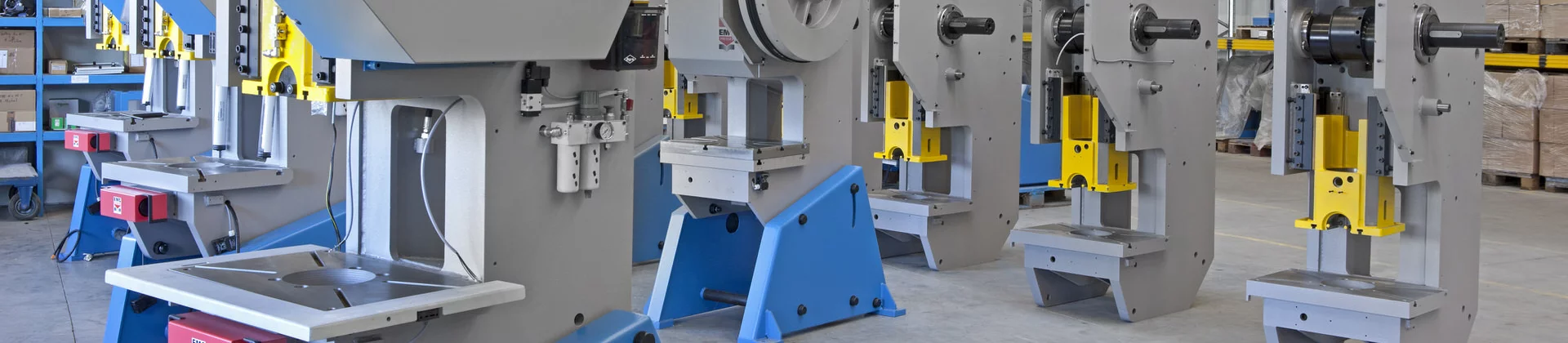

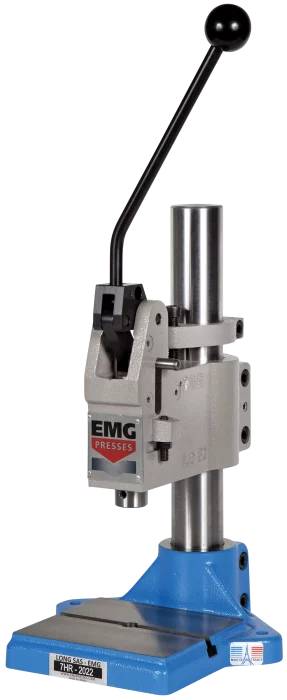

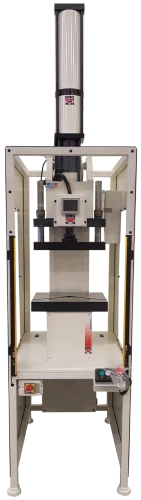

French manufacturer of industrial presses

EMG is a family-owned company that has developed over three generations a wide range of products and services appreciated by manufacturers worldwide.

Used successfully since 1966 in many sectors of industry, EMG presses make the manufacturer a first rank partner, offering equipment synonymous with precision and endurance.

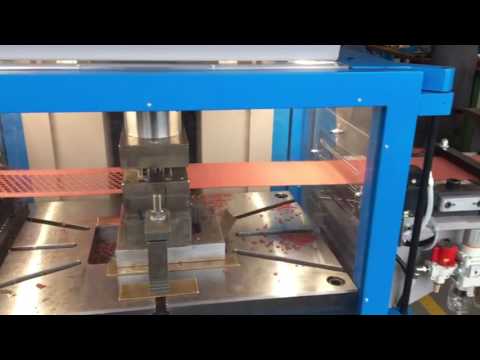

EMG's test room for your samples

EMG offers its customers a showroom and a test laboratory at the company's headquarters, adjacent to our production facilities, where all our models can be used and handled.

In this department, all press tests are carried out every week on samples submitted by our customers and future buyers.

"Strong arguments "from standard to custom-made

Thanks to the high performance reserve of each industrial press model and the high overall precision, the most diverse operations can be carried out flexibly.

The entire EMG range offers a wide choice of options and adaptations to meet the needs of each application: the LONG company is thus committed to designing and equipping the special machines required by the specific activities of each trade.

Certified ISO-9001 since 2000, EMG presses are delivered with a service manual, CE conformity certificate and drawings. They benefit from a one year warranty, parts, labor and travel.